Leak Repair Kit

PACKAGE:

1 roll of Wrap Seal Fiberglass Tape

2″ x 5′ (50 mm x 1.2 m)

2″ x 6′ (50 mm x 1.8 m)

2″ x 12′ (50 mm x 3.6 m)

3″ x 9′ (75 mm x 2.7 m)

4″ x 12′ (100 mm x 3.6 m)

1 unit of Seal Stic Quick Cure Epoxy

1 pair of latex gloves

Operating instruction

MODEL:

- WS0206

- WS0212

- WS0309

- WS0412

- WS0420

- WS0430

- WS0620

- WS0630

- WSP500

LEAK REPAIR KIT

WRAP SEAL QUICK REPAIR KIT FOR PIPE LEAKS

FEATURES:

- Repairs leak in 30 minutes

- Applicable to pipes up to 18″ (457 mm) diameter

- Applicable on any metal or non-metal pipes

- Repairs T-joint, elbow joint, valve thread, valve body

- Withstand pressure up to 400 psi (28 kg/cm2)

- Withstand temperature up to 200 °C (392 °F)

- Safe for drinking water and resistant to most chemicals

- Reinforce and strengthen pipe after repair

- Permanent repair and extend service life of pipes

APPLICABLE MATERIAL:

- Steel

- Copper

- Aluminium

- Galvanized steel

- PVC

- CPVC

- Stainless steel

- Polyethylene

- Polypropylene

- Cast-iron

- Concrete

- FRP/GRE

CHEMICAL RESISTANCE:

- Oil

- Water (drinking water, wastewater, steam)

- Solvents (acetone, toluene, MEK, ethyl alcohol)

- Mild acids (hydrochloric acid, sulfuric acid) and alkalis

- Chemical (ethylene glycol, xylenes, ammonia)

- Hydrocarbons

- Bases

- Slurries

- Fuels (petroleum, diesels, gasoline)

- Gases (LNG, LPG)

- Organic salts

WORKING TIME (FIBERGLASS TAPE):

1 minute at 30 °C (86 °F)CURING TIME:

- 30 minutes at 30 °C (86 °F)

- Heat may be applied to decrease curing time

- Unopened foil pouch may be immerse in cold water prior to repair to add working and curing time.

APPLICATION:

- Pipe repairs

- Offline repairs

- Sealing joints

- Hazardous material spill control

- Reinforce thinning walls

- Abrasion protection

- Structural reinforcement

- Repairs in hard to reach areas

- Underwater repairs

OPERATING TEMPERATURE:

- Continuous – From -29 °C (-20 °F) up to 200 °C (392 °F)

- Intermittent – From 200 °C (392 °F) up to 320 °C (570 °F)

OPERATING PRESSURE:

- Recommended for pressure up to 400 psi (28 kg/cm2)

- (Results vary depending on pipe size, type of pipe, hole size, pipe content and method of application)

APPLICABLE INDUSTRIES:

- Building and Facilities

- Electronics

- Industrial Processing

- Oil and Gas

- Military

- Offshore

- Petrochemicals

- Etc

TECHNICAL DATA:

| Pressure tested | : | 1/2″ (15 mm) steel pipe with 1/8″ (3 mm) hole when repaired with Wrap Seal withstands 4000 psi (281 kg/cm2) |

| 1/2″ (15 mm) steel pipe with 1/2″ (13 mm) hole when repaired with Wrap Seal withstands 600 psi (42 kg/cm2) | ||

| Tensile strength | : | 3920 psi (276 kg/cm2) |

| Bond strength | : | 230 psi (16 kg/cm2) |

| Tensile elongation | : | 1.2 % ± 0.7 % |

| Compressive strength | : | 13750 ± 530 psi (967 ± 37 kg/cm2) |

| Yield strength | : | 2260 psi (159 kg/cm2) |

| Cured hardness | : | 82 Shore D |

| Pipe size | Number of rolls / size required. | ||

| 50 psi (4 kg/cm2) 10 plys | 150 psi (11 kg/cm2) 15 plys | 400 psi (28 kg/cm2) 20 plys | |

| ½” (15mm) | 1 A | 1 A | 1 A |

| ¾” (20mm) | 1 A | 1 A | 1 A |

| 1″ (25mm) | 1 A | 1 A | 2 A |

| 1¼” (32mm) | 1 A | 2 A | 3 A |

| 1½” (40mm) | 2 A | 2 A | 1 B |

| 2″ (50mm) | 1 B | 1 B | 1 B |

| 2½” (65mm) | 1 B | 1 B | 2 C |

| 3″ (80mm) | 1 B | 2 C | 2 C |

| 4″ (100mm) | 1 B | 2 C | 3 C |

| Pipe size | Number of rolls / size required | ||

| 50 psi (4 kg/cm2) 10 plys | 150 psi (11 kg/cm2) 15 plys | 400 psi (28 kg/cm2) 20 plys | |

| 5″ (125mm) | 2 C | 2 C | 3 C |

| 6″ (150mm) | 2 C | 2 C | 4 C |

| 8″ (200mm) | 2 C | 3 C | 5 C |

| 10″ (250mm) | 3 C | 4 C | 6 C |

| 12″ (300mm) | 4 C | 5 C | 8 C |

| 14″ (350mm) | 4 C | 6 C | 8 C |

| 16″ (400mm) | 5 C | 7 C | 9 C |

| 18″ (450mm) | 5 C | 8 C | 9 C |

| > 18″ (450mm) | Contact SealXpert for recommendations | ||

| Roll size | A (2″ x 5′) (50mm x 1.2m) | A (2″ x 6′) (50mm x 1.8m) | B (2″ x 12′) (50mm x 3.6m) | B (3″ x 9′) (75mm x 2.7m) | C (4″ x 12′) (100mm x 3.6m) |

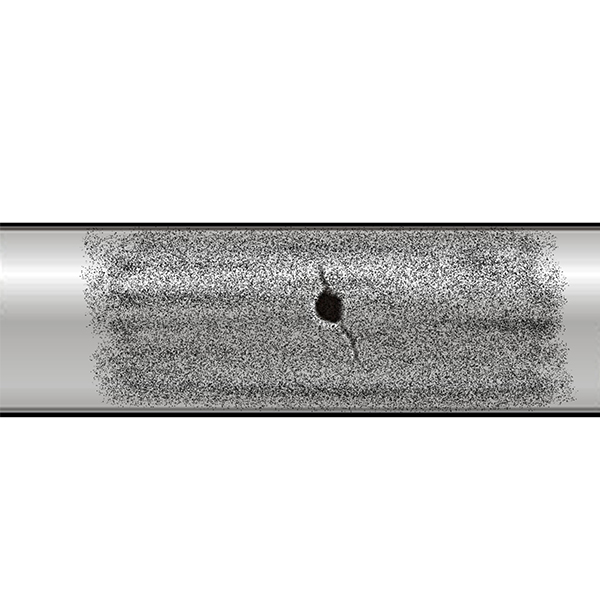

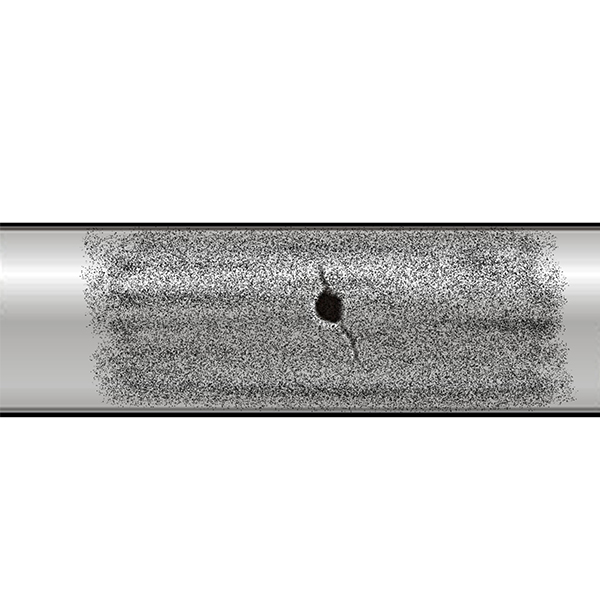

WRAP SEAL OFFLINE LEAK REPAIR PROCEDURE:

1 Stop the pipe flow

Stop the pipe flow

Stop the pipe flow

Stop the pipe flow2 Roughen the area to be repaired

Roughen the area to be repaired

Roughen the area to be repaired

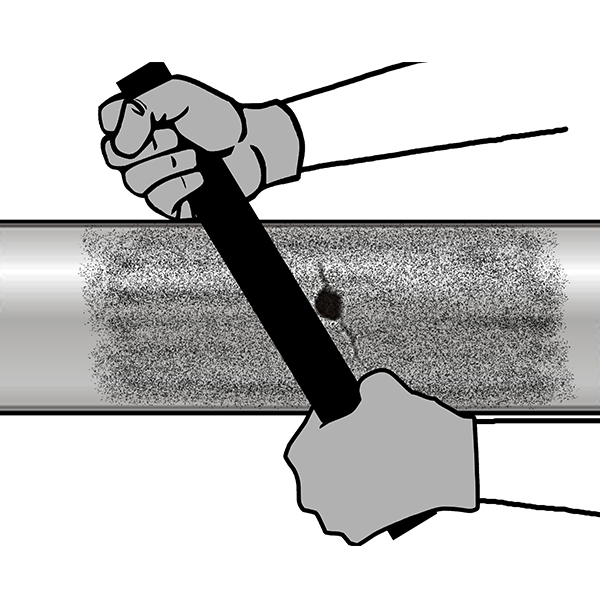

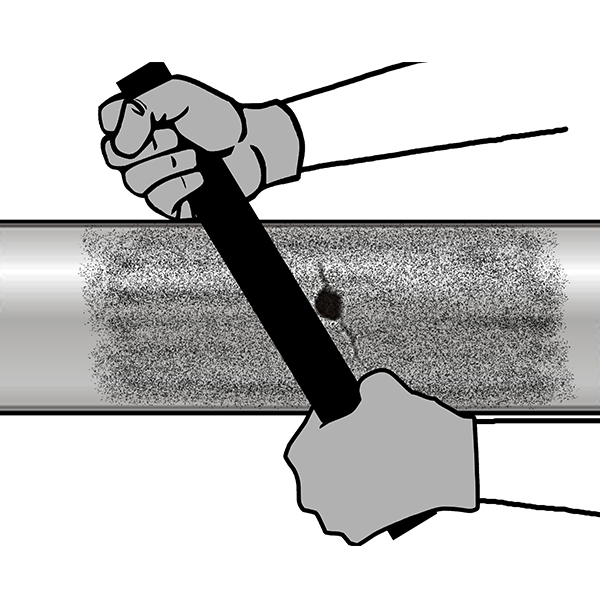

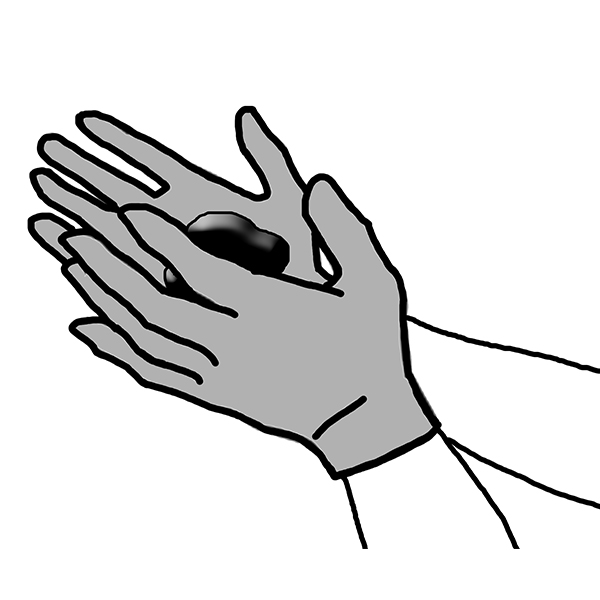

Roughen the area to be repaired3 Knead the Seal Stic

Knead the Seal Stic

Knead the Seal Stic

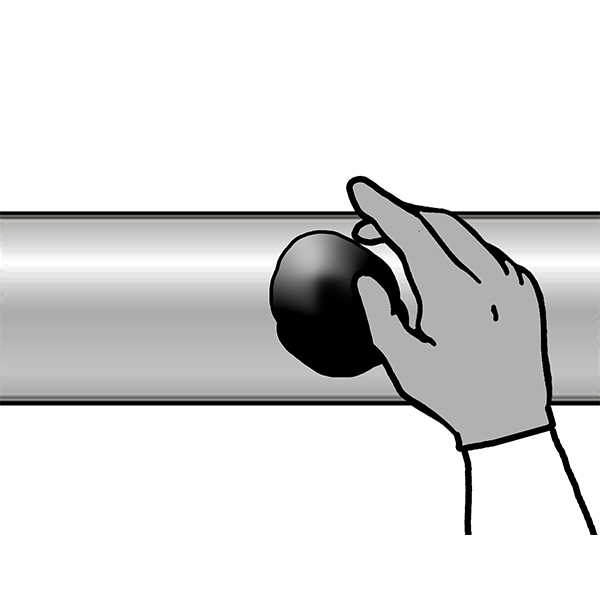

Knead the Seal Stic4 Apply the Seal Stic to fill in holes or crack of the damaged or leak area.

Apply the Seal Stic to fill in holes or crack of the damaged or leak area.

Apply the Seal Stic to fill in holes or crack of the damaged or leak area.

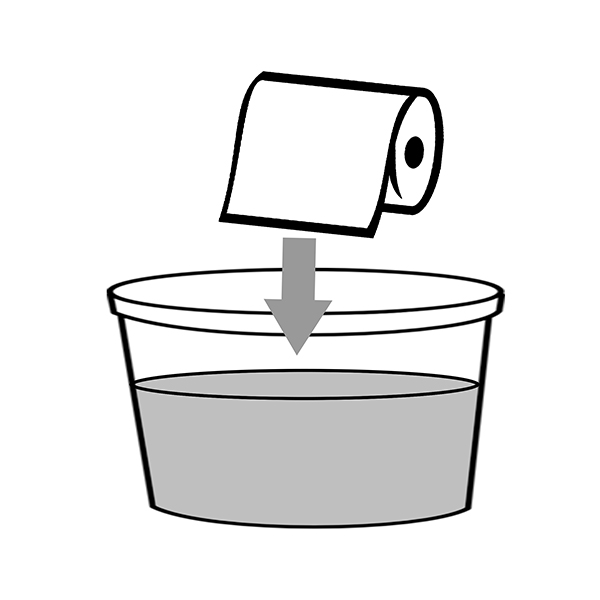

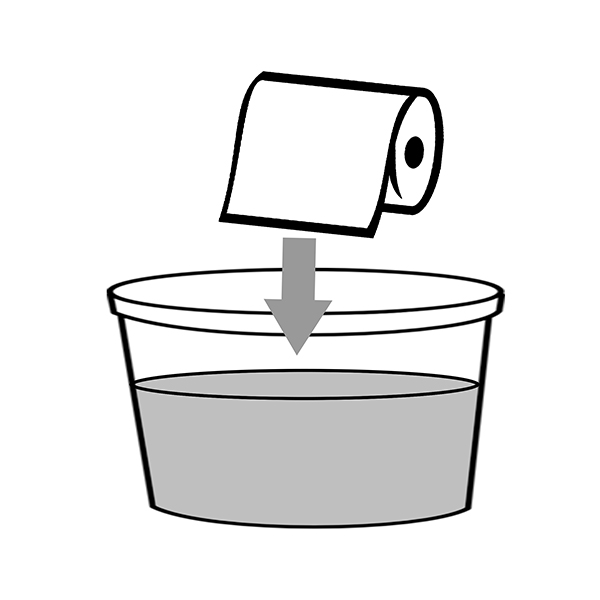

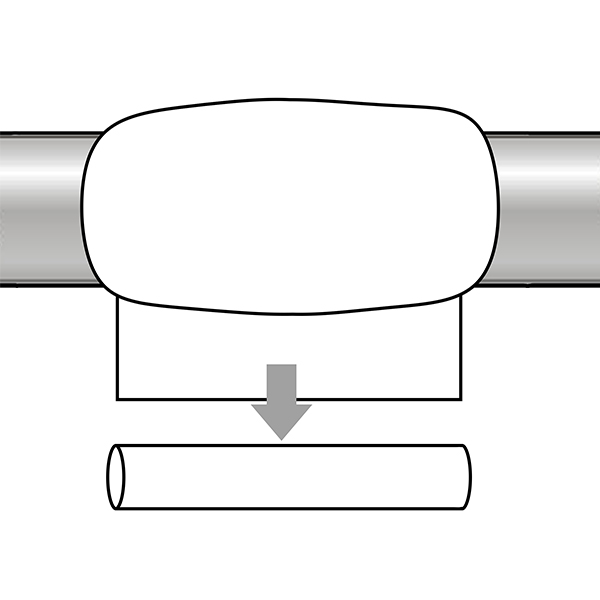

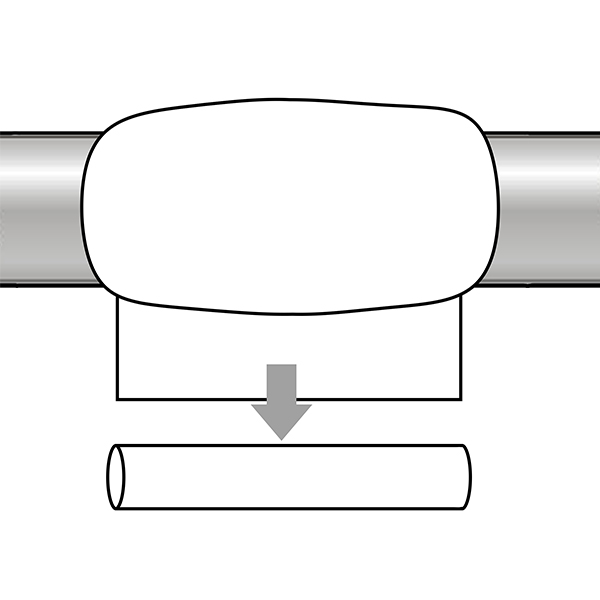

Apply the Seal Stic to fill in holes or crack of the damaged or leak area.5 Immerse the Wrap Seal Fiberglass Tape into water

Immerse the Wrap Seal Fiberglass Tape into water

Immerse the Wrap Seal Fiberglass Tape into water

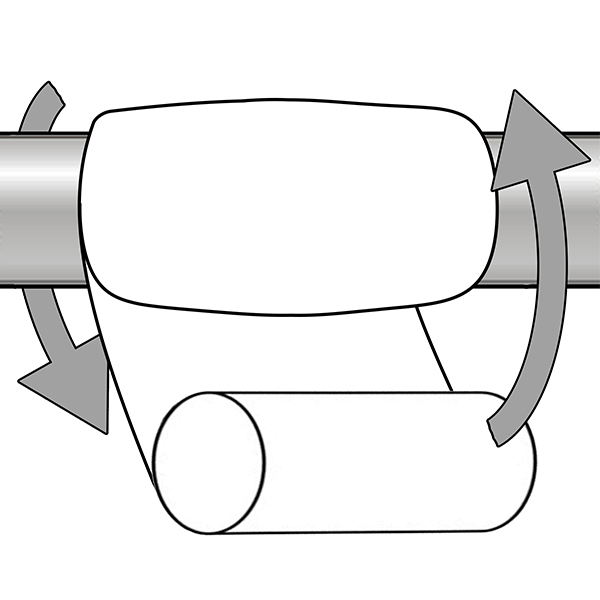

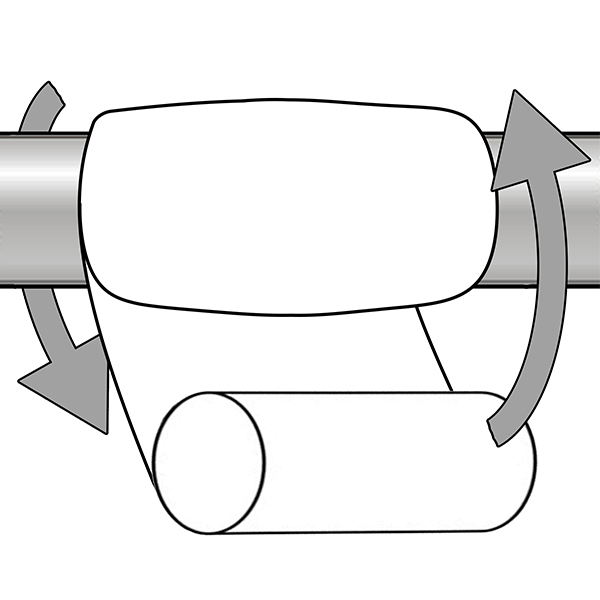

Immerse the Wrap Seal Fiberglass Tape into water6 Wrap the Wrap Seal Fiberglass Tape around the repair area as tightly and evenly as possible, using the entire roll

Wrap the Wrap Seal Fiberglass Tape around the repair area as tightly and evenly as possible, using the entire roll

Wrap the Wrap Seal Fiberglass Tape around the repair area as tightly and evenly as possible, using the entire roll

Wrap the Wrap Seal Fiberglass Tape around the repair area as tightly and evenly as possible, using the entire roll7 Discard the plastic tube at the end of the roll

Discard the plastic tube at the end of the roll

Discard the plastic tube at the end of the roll

Discard the plastic tube at the end of the roll8

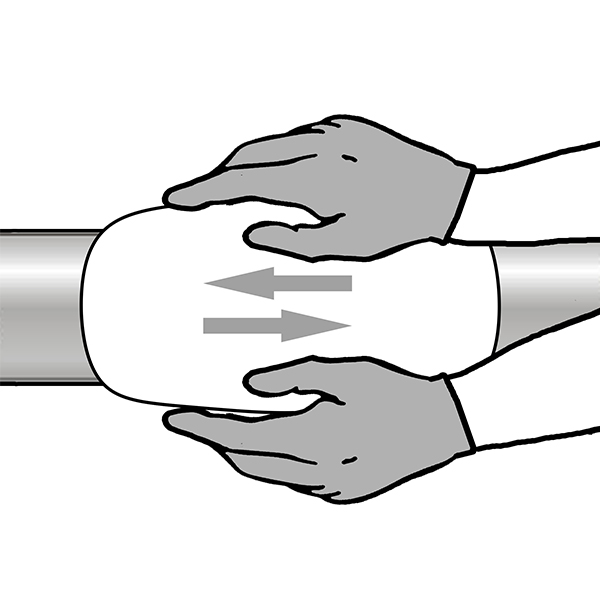

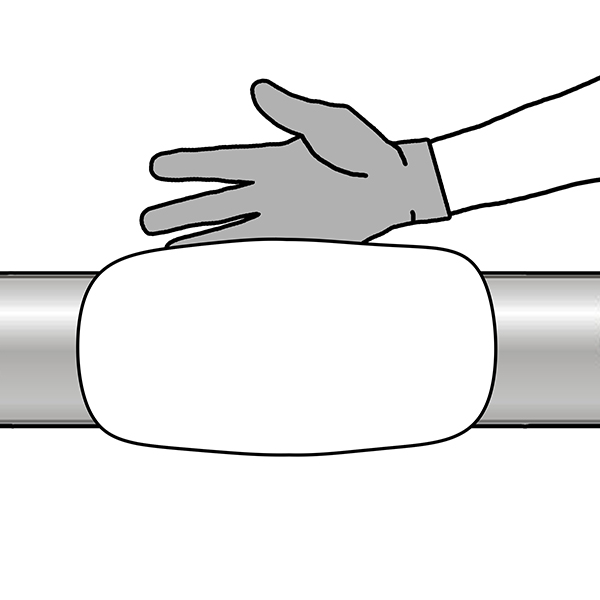

Wet gloves in water and quickly compress the bubbling resins back into the fiberglass wrap.

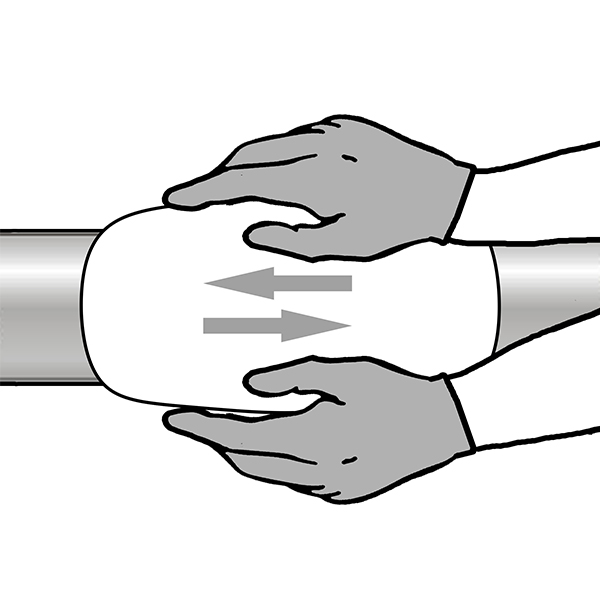

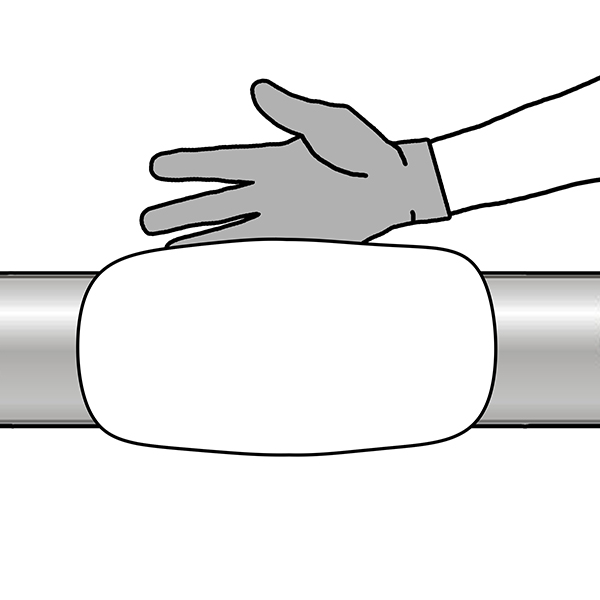

9 Continue to polish the wrap until all bubbling has stopped. Repair completed with smooth and hard ivory appearance.

Continue to polish the wrap until all bubbling has stopped. Repair completed with smooth and hard ivory appearance.

Continue to polish the wrap until all bubbling has stopped. Repair completed with smooth and hard ivory appearance.

Continue to polish the wrap until all bubbling has stopped. Repair completed with smooth and hard ivory appearance.Hubungi Kami:

PT. TRIAS NATHOMI CHEMINDO

Jl Industry KAV 9-11 Komplek Wisma GK Blok SB03

Kemayoran Jakarta Pusat - 10710

Telp: 021-62302799, HP.WA: 081270868021

https://www.sealerproduct.com/

Post a Comment

Note: Only a member of this blog may post a comment.